Construction Notes

In the spring of 2009…

we began the crazy construction experiment that would, with some luck, become our winery facility. Unable to find a design/build company that meshed with our needs, we combined several materials we liked with the help of an architect and created a structure that is well suited for both processing and sales. These photos show some of the details of our unusual project.

A good foundation…

is necessary for future success. Our situation called for a super-duper footer that was extra wide at the ends. This served both to tie together the steel arch walls underground and also to support the block wall set in a few feet from the outside dimensions. Even more concrete was poured as underground beams across the 40-foot width.

Strengthened by steel…

a support beam was poured over the protruding rebar and would become the platform on which our steel sill plates would rest. Anchor bolts were driven into the beams and the plates were settled over them in very close tolerance. Rolls of putty-like caulk were applied to the exterior footprint where the wall panels would stand.

The joyous day came…

when the stacks of steel panels began a short parade from our garage to the their new home. Building materials and tanks occupied our garage for too long as construction was delayed.

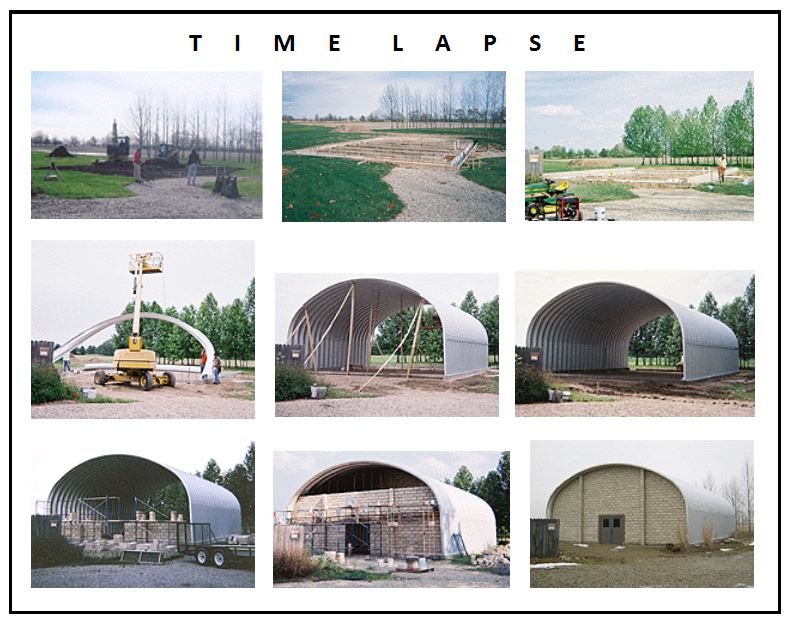

A bed of gravel…

provided a useful floor until the time a concrete floor could be poured. The instructions called for building each arch flat and standing it up. With our dimensions of 20 feet high and 40 feet wide, the arch was far too wobbly to manage. Half-arches weren’t much better. The persistent crew resorted to adding one piece at a time, then tightening the bolts after all was in place. The “time lapse” photos (see below) show the precarious start with the first arch. We learned the most important goal is to have the height exactly right from the start as it impacts everything and is impossible to change later.

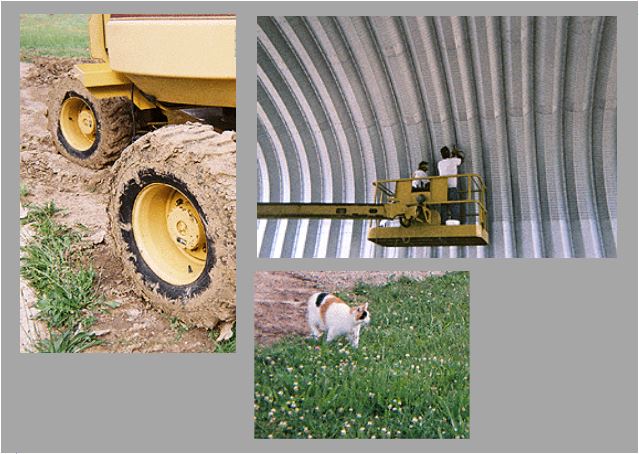

The right equipment…

makes all the difference and the drive-able lift was certainly a helpful tool. It was undaunted by our muddy terrain and provided accurate placement of the crew throughout the project. They are shown here (right) giving the bolts a final tightening. Chardonnay, the cat, was kept indoors on days with too many trucks in the driveway but insisted on inspecting the worksite after hours.

Blocks…

glorious blocks, so earthy and rustic! Pleased with their appearance, we soon discovered how challenging the installation was with the required vertical rebar in the walls. But committed to our crazy experiment, and with much patience from our block mason, the plan proceeded. A shellac barrier was applied to the interior where the blocks extended into the “pocket” of the metal walls. This helps prevent a corrosive reaction between the mortar and the galvanized surface. Lines of caulk at the horizontal joints keep the mortar from weeping down the exterior.

Made-to-order…

the lintels over our openings provide a horizontal tie for the lower courses and vertical support for the upper courses of block. A timely tack weld keeps progress moving.

A warm face…

welcomes those who would inspect our otherwise cold building. With the scaffolding gone, the effect becomes apparent. Pilasters were designed to add visual interest and provide a natural expansion joint. The swinging doors on the front and back entrances concluded construction efforts for 2009. Plywood would cover the garage door area through the winter.

Decorative Arbors…

an integral part of our overall site design, were included on our building permit and considered a priority in warming up our otherwise steely building. One large arbor will provide shelter and atmosphere for outdoor seating just off the front entrance of the winery. Two smaller arbors positioned along each steel side will host welcoming vines.

This do-it-yourself portion was begun in late March of 2010. Concrete piers were poured with anchor bolts. Then metal brackets fastened pressure-treated posts to the piers. One arbor serves a dual purpose as it supports the control panels for the dosing tank and blower of our septic system.

It took every ladder…

apparently, in our possession to engineer the bracing on the front entrance overhang. We even borrowed a taller step ladder from a neighbor when we stained the cedar lumber. The metal roofing panels match the garage and house. So shiny and rich in color this rectangle looks like a giant chocolate bar.

The vineyard entrance…

features a vertical lift garage door that preserves valuable space inside. Deliveries of bottles and other supplies will be made through this service entrance. Grapes harvested from our vineyard will be crushed in this area.

Space was tight…

in many ways when planning our septic system. We had already used the most appropriate spot on the 10 acre property for the residence septic system installed in 1992. The winery facility needed positioned on favorably high ground. For two years, septic designers struggled with several layouts trying to utilize the suitable soils and situations still available for the commercial septic system. The final solution required a grease trap, a pre-treatment digestion tank and dosing tank. A narrow space was found for the tanks on the east side of the building. The photo shows the placement of the third tank that will pump a good distance west of the building to an area that slopes appropriately.

Because of dense trees…

a field of irrigation tubing created a smaller footprint and caused less root damage than a conventional finger system. Two mature trees were removed from the area and many more had their feet tickled by the big equipment. Irrigation tubing with built-in emitters is pulled through slits in the soil made at prescribed intervals. A 6-inch perimeter drain surrounds the field. Pre-treated effluent is dispersed to the tubing from manifold pipes on the south side of the field.

The dust had barely settled…

before we dug through the driveway again, this time to lay the water line. By late summer the ground was getting pretty hard for lack of rain but the excavator cut through it like child’s play. A deep limestone well is the source of water for the winery. We were able to feed the seamless water line through a planned conduit in the foundation and by the end of the second day the dirt and gravel was all back in place.

Final decisions…

were crucial when planning under-slab plumbing and electrical conduit. Trying to anticipate every need and future need caused some sleepless nights. Trenches were made in the pea gravel for thickened areas in the slab for supporting interior walls. Rolls of insulation and vapor barrier were all put in place before it would all be “set in stone.

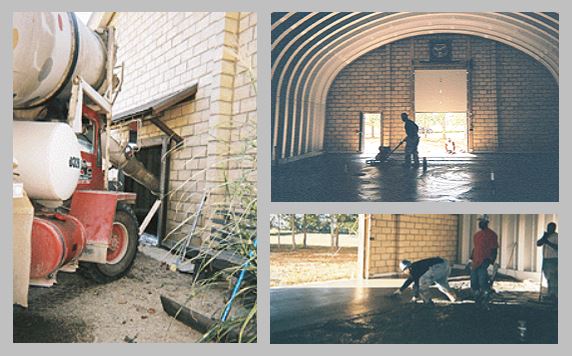

Up close and personal…

the concrete truck delivers the last of 4 loads of concrete for our floor through the front door. Working from the back to the front, the first 3 loads were pumped inside and kept 11 people plenty busy.

Minimum requirements…

was the goal for this phase of construction. Actually we had planned to complete the first building permit with only a gravel floor. However, since tight space around the septic tanks delayed installation of the third arbor, by the time we were ready for a final inspection we decided instead to amend the permit for plumbing and pour the floor in this first phase. A short list of necessary fixtures were installed to create a starter nook for winemaking over the winter of 2010-2011.